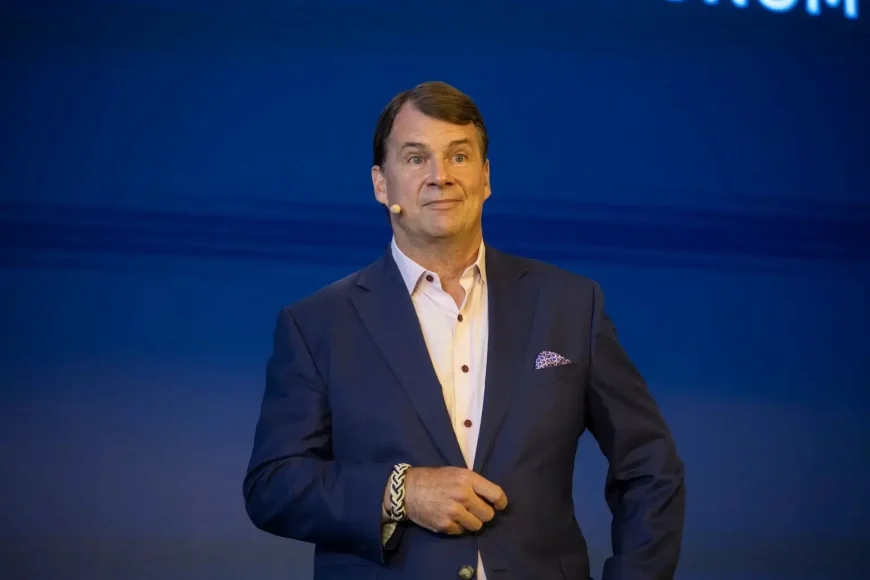

Ford CEO Jim Farley laments he can’t fill 5,000 mechanic

Ford has been unable to fill nearly 5,000 mechanic positions despite offering salaries of $120,000 per year—leading the company's chief executive to warn of a severe shortage of skilled workers in the US.

,

Ford has been unable to fill nearly 5,000 mechanic positions despite offering salaries of $120,000 per year—leading the company's chief executive to warn of a severe shortage of skilled workers in the US.

"We're in trouble in our country. We're not talking about it enough," Ford CEO Jim Farley said in an episode of the "Office Hours: Business Edition" podcast published earlier this week.

"We have over a million vacancies for critical jobs, emergency services, trucking, factory workers, plumbers, electricians, and craftsmen."

Ford CEO Jim Farley said that despite offering salaries of $120,000 per year, he has been unable to fill nearly 5,000 mechanic positions.

Farley said it takes about five years to learn the skills needed to remove a diesel engine from a Ford Super Duty truck—and not enough people are being trained in the country.

"We don't have trade schools," he said angrily.

Earlier this year, Ford launched a $4 million scholarship initiative for auto technicians.

"We're not investing in educating the next generation of people like my grandfather, who had nothing, who built a middle-class life and a future for his family," Farley said.

His grandfather was employee number 389 at Ford and worked on the company's flagship Model T.

Rich Garrity, president of the National Association of Manufacturers and a board member of Ford Motor Company, agreed with Farley's grim assessment.

"I think his comments were absolutely correct," he told The Post.

"We don't just have a shortage of workers, I would say we really have a shortage of skills that connect to 21st-century manufacturing needs," said Garrity, chief business unit officer at additive manufacturing firm Stratasys.

The shortage of mechanics at Ford is part of a broader crisis affecting manufacturing and skilled trades.

As of August, the Bureau of Labor Statistics counted more than 400,000 vacant manufacturing positions despite a 4.3% unemployment rate.

Last year, the Manufacturing Institute and Deloitte surveyed 200 manufacturing firms and found that recruiting and retaining employees was the biggest challenge for more than half.

According to the National Automobile Dealers Association, the automotive industry alone faces an annual shortage of approximately 37,000 trained technicians.

BLS US estimates that by 2033, there will be an average of 67,800 vacancies for automotive service technicians and mechanics each year.

Farley expressed disbelief at this massive shortage, saying: "An elevator and a tool bay and no one to work in it—are you kidding? No."

Part of the problem is demographics. Baby Boomers are retiring from these occupations faster than Millennials and Generation Zers.

But it's not just a matter of numbers. According to Garrity, the skills required to work in manufacturing have evolved.

"Most of the opportunities we're seeing today aren't just old-fashioned manual skills, but a mix of manual and digital skills," he said.

"This is an area where we're still seeing a big gap."

"The worst part, according to Garrity, is that trade schools and community colleges haven't kept pace with technology.

"Community colleges and career tech programs do a good job of providing basic training, but we often see them become outdated given how rapidly things are changing from a technological perspective," he said.

"If we talk about additive manufacturing, robotics, automation, EV batteries, we see very few courses that can keep pace."

There are signs of change. Last year, trade school enrollment saw a 16% increase—a record high since the National Student Clearinghouse began collecting data in 2018.

Meanwhile, four-year college enrollment declined 0.6% from the fall of 2020 to the fall of 2023, and trade school enrollment increased 4.9% over the same period.

Garrity said this change in education And it reflects the changing reality of career paths.

"For many years in America, it's been the case that you go to a four-year college and things... you," he said.

"And the reality is that that path is no longer the same. In many cases, the more productive path is to go to a technical college or take an apprenticeship and learn some skills at a very young age."

Ford has tried to make its jobs more attractive. In its recent contract with the United Auto Workers union, the company abandoned its lowest pay level and promised a 25% pay increase over four years.

But if there aren't enough trained workers available, higher wages alone won't solve the problem.

"A different level of skill is needed, and frankly, we don't have a pipeline of workers who come prepared with those skills," Garrity said.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0